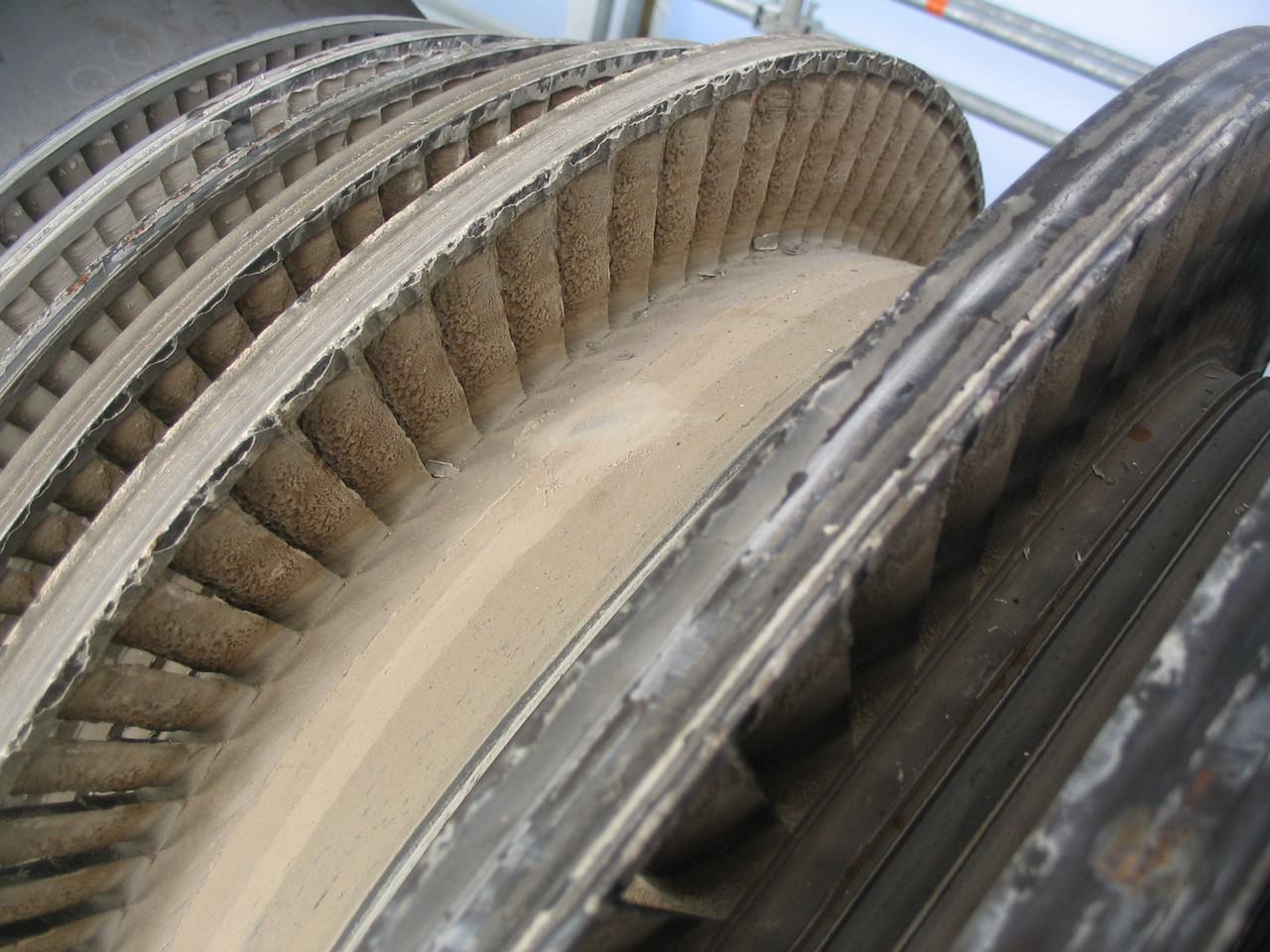

Dust-free sandblasting process

This process is often used in power plants in the preparation of turbine and valve housings, bypass stations, welded joints, pipe bends and steam lines for various tests. Previously, this work was performed by grinding, which is extremely dirty and labor-intensive, and popular with neither the customer nor with the operators doing the work. Another benefit is that, unlike grinding, these operations can be carried out relatively quickly.

The dust-free sandblasting process has already proven to be highly effective in the following areas of application:

• Turbine upper and lower casings

• Valve bodies

• Bypass stations

• Pipe bends

• Welded joints

• Steam lines